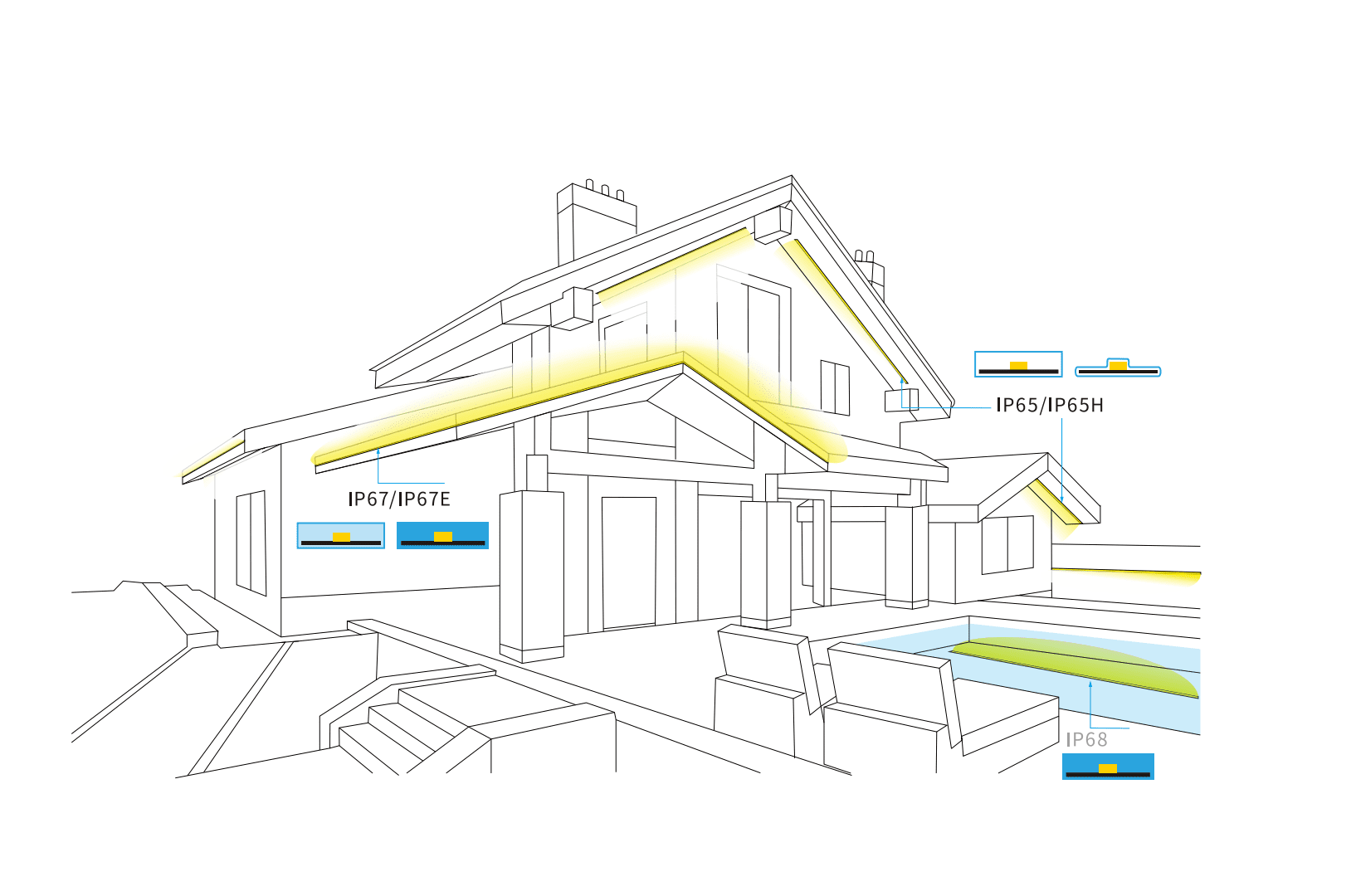

Now, let’s break down the three most common waterproof ratings you will encounter for LED strips.

IP65 LED Strips: Jet Water Protection

An IP65-rated LED strip is fully dust-tight and protected against water jets from any direction.

- Test Standard: It is tested using a 6.3mm nozzle spraying water from any angle without harmful effects.

- Advantages and Limitations:

- ✔️Excellent for most outdoor applications where it is not directly exposed to standing water or immersion (e.g., under eaves, on walls, for signage).

- ✔️Often more cost-effective than higher IP ratings.

- ❌ Not suitable for temporary or continuous immersion.

IP67 LED Strips: Temporary Immersion Protection

An IP67 rating offers a significant step up in water protection. It is dust-tight and can withstand temporary immersion in water.

- Test Standard: The strip is immersed in 1 meter of water for 30 minutes without leakage.

- Advantages and Limitations:

- ✔️Ideal for outdoor landscape lighting, floor lighting, and areas that may experience flooding or heavy rain.

- ✔️Provides a safety margin for applications where temporary water exposure is possible.

- ❌ Not designed for long-term, continuous pressure from submersion.

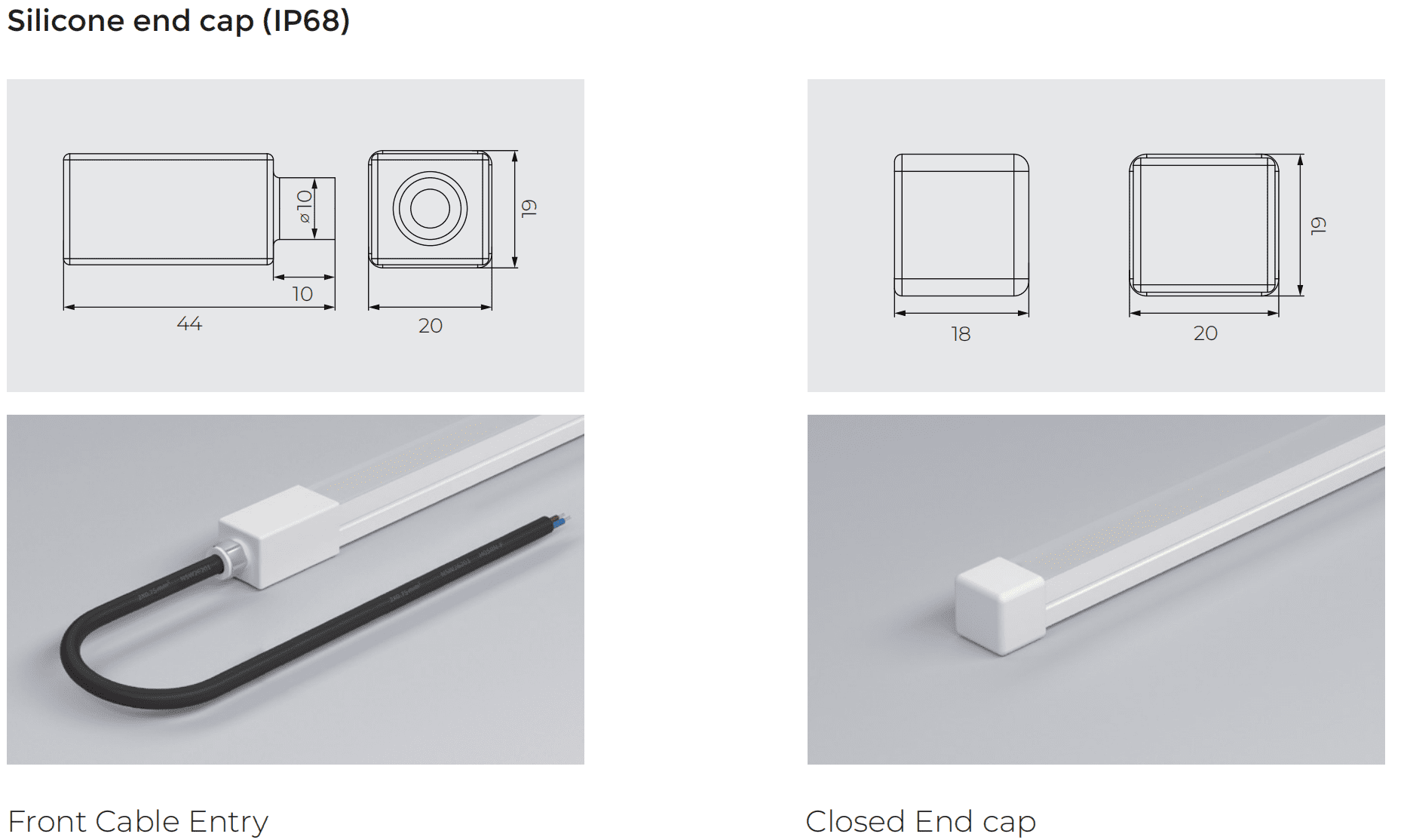

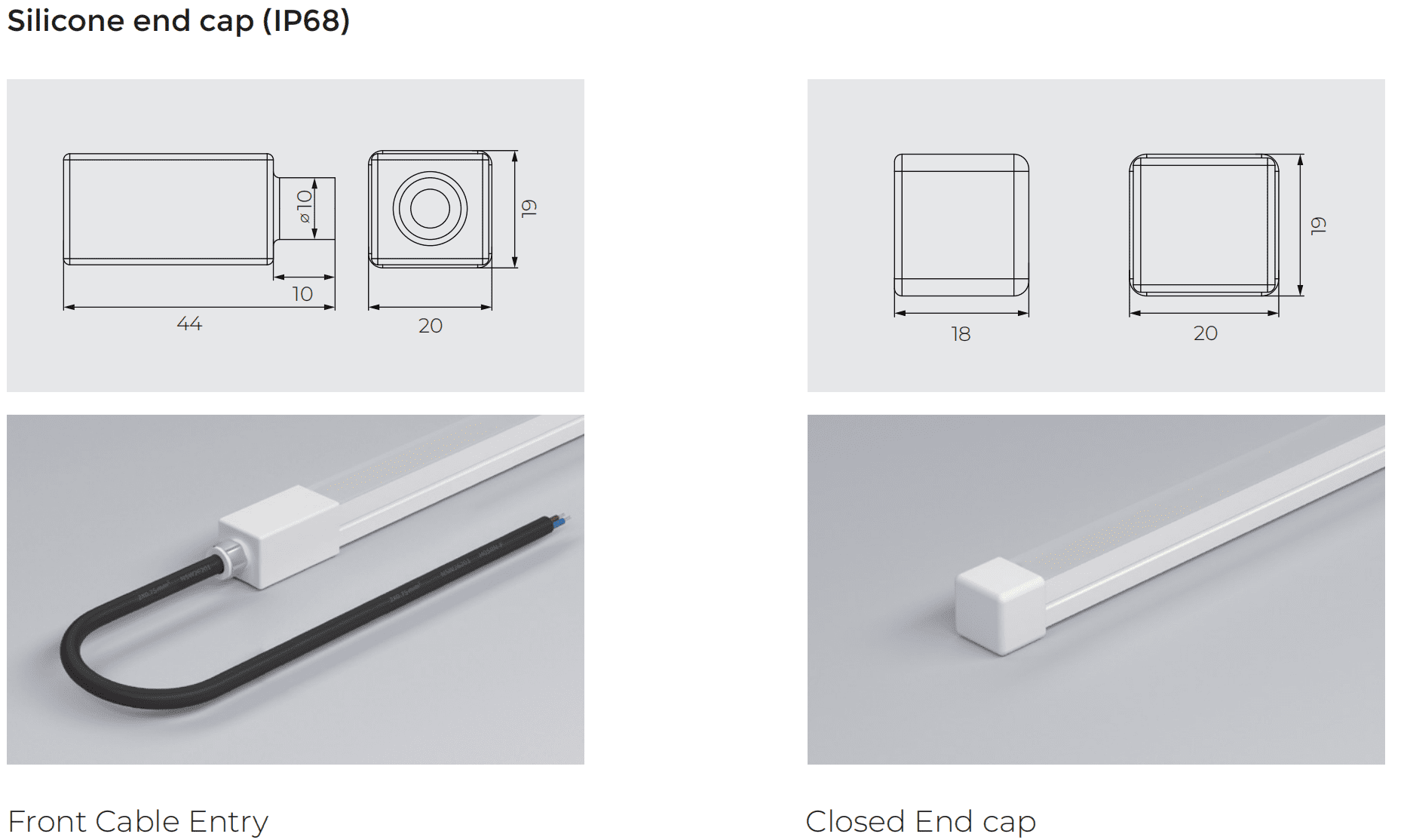

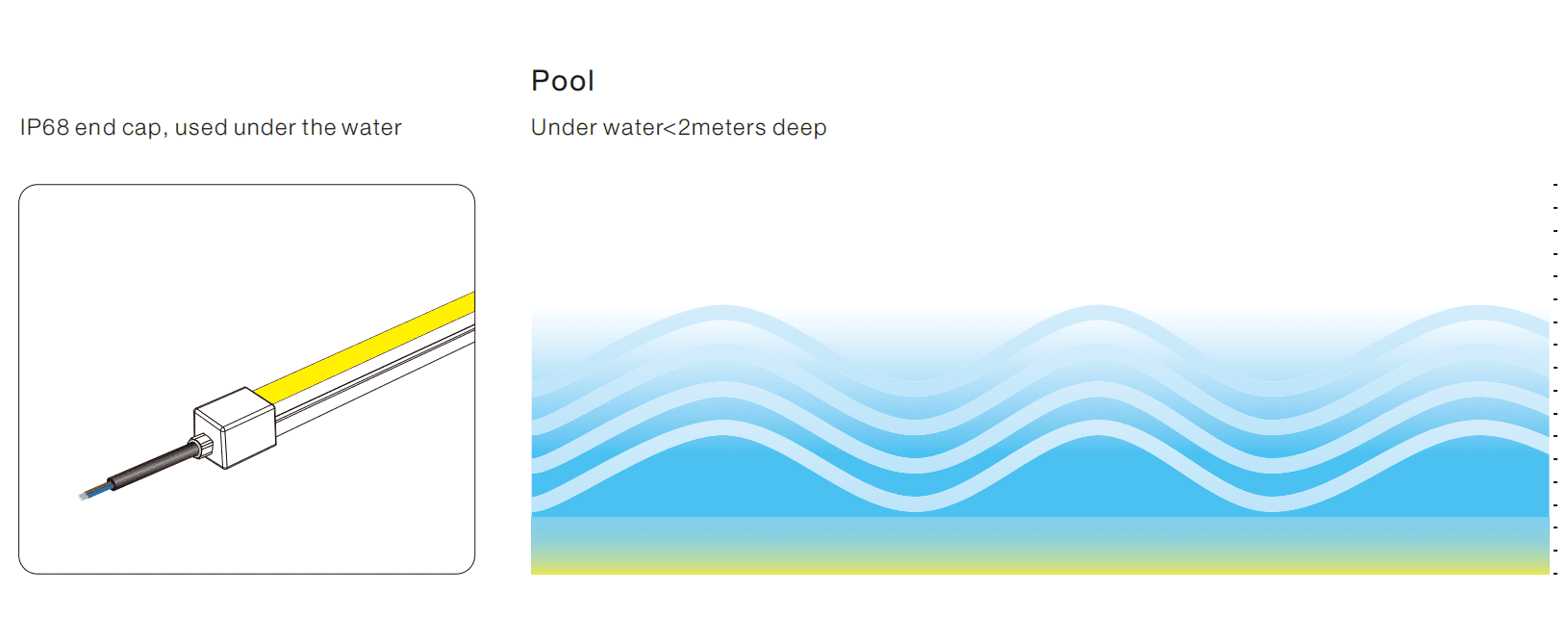

IP68 LED Strips: Continuous Underwater Protection

IP68 is the highest level of protection commonly available for LED strips. It is designed for continuous immersion under specified conditions.Thus the test requirements are more difficult and strict.

- Test Standard: The testing is more rigorous than IP67, with the manufacturer specifying the exact depth and duration (e.g., up to 1.5 meters for continuous use).

IP68 Rating Test Standards for LED Strips based on IEC 60529.

This is the fundamental international standard that defines the degrees of protection provided by enclosures for electrical equipment.

Test Description

The equipment is suitable for continuous immersion in water under conditions which shall be specified by the manufacturer. The test is more severe than IPX7. The key difference is that for IPX7, immersion is for 30 minutes at a depth of 1 meter. For IP68, LUMIWISE request they must be greater than the IPX7 requirements.

Typical Test Procedure for IP68 LED Strips

When we perform these tests, the general procedure is as follows:

1)Pre-conditioning:

The LED strip is placed in a chamber at a specified temperature (e.g., 5°C to 15°C lower than the water temperature) to create a slight vacuum inside the enclosure upon immersion.

2)Immersion Test:

2.1 .The LED strip is fully immersed in a tank of water to the depth specified by the manufacturer (e.g., 1.5 meters).

2.2It is held at this depth for the specified duration (e.g., 30 minutes).

2.3The water should not be contaminated to avoid influencing the results.

3.Post-Test Examination:

3.1After removal from the water, the LED strip is carefully inspected for any signs of water ingress.

3.2The primary check is for the presence of water inside the silicone jacket or on the PCB itself.

3.3The strip must remain fully functional with no electrical failures.

- Advantages and Limitations:

- ✔️ The only rating truly safe for swimming pools, fountains, and permanent underwater features.

- ✔️ Offers maximum reliability and longevity in the harshest wet environments.

- ❌ Typically the most expensive option due to the superior sealing required.

IP Rating Comparison at a Glance

| IP Rating |

Protection Against Dust |

Protection Against Water |

Ideal Application Scenarios |

| IP65 |

Complete |

Low-pressure water jets |

Covered outdoor areas, indoor signs, sheltered architectural lighting

|

| IP67 |

Complete |

Complete Temporary immersion (30 mins) |

Landscape lighting, floor lighting, temporary water features, bathrooms

|

| IP68 |

Complete |

Continuous submersion |

Swimming pools, fountains, permanent underwater installations |