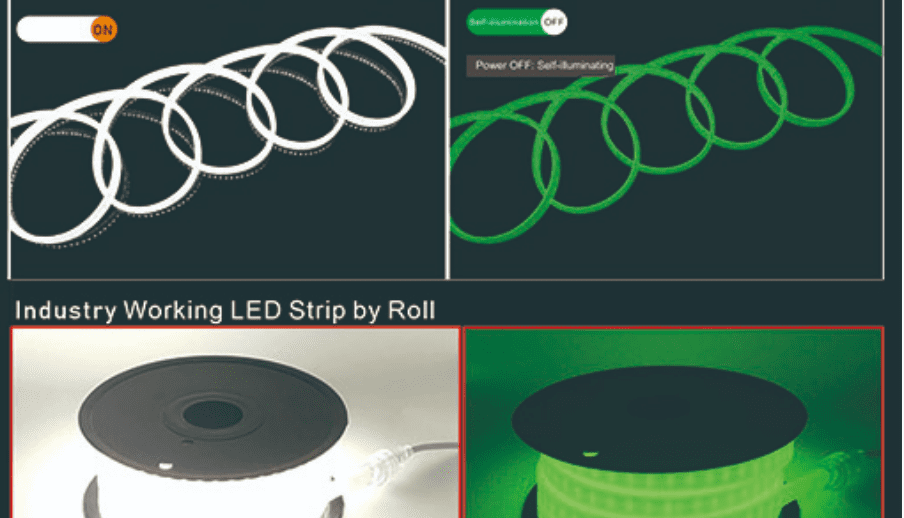

High Voltage LED flexible strip lights are now one of the most popular ways to brighten homes, shops, outdoor spaces and tunnel lighting and working light. They’re flexible, energy-efficient, and easy to install. But when you need long, continuous lighting, like on building edges or outdoor signs, because regular 12V or 24V strips can lose brightness and need extra power supplies.

That’s where high-voltage LED strip lights (110V/220V) work best. They connect directly to AC power, giving bright, even light across long distances without dimming. Whether it’s for decorating, highlighting architecture, or illuminating large areas, these strips are a smart and powerful option. This post will explain what they are, how they work, their benefits, and how to choose the right one.

This is typical applications for LED high Voltage strip in Tunnel