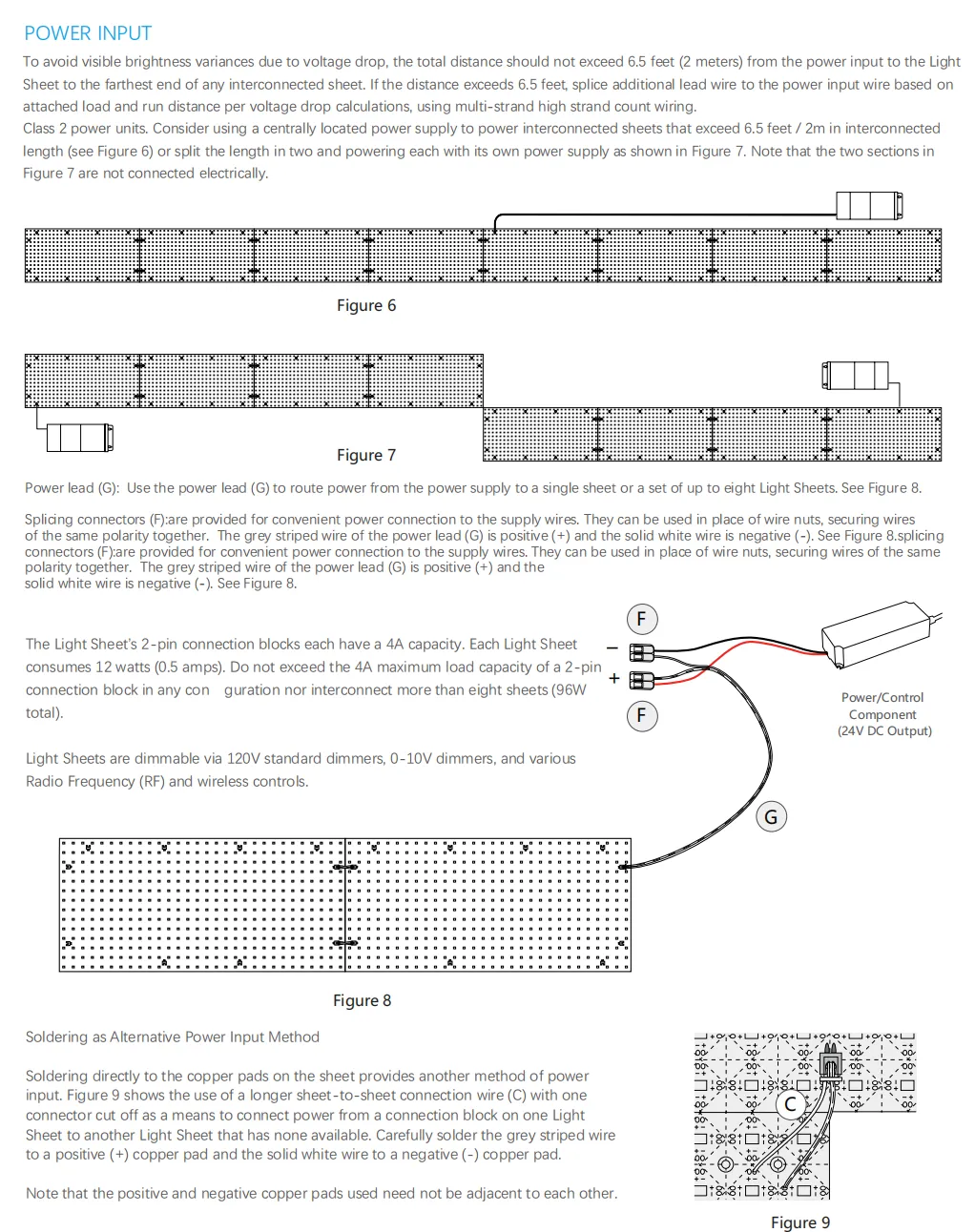

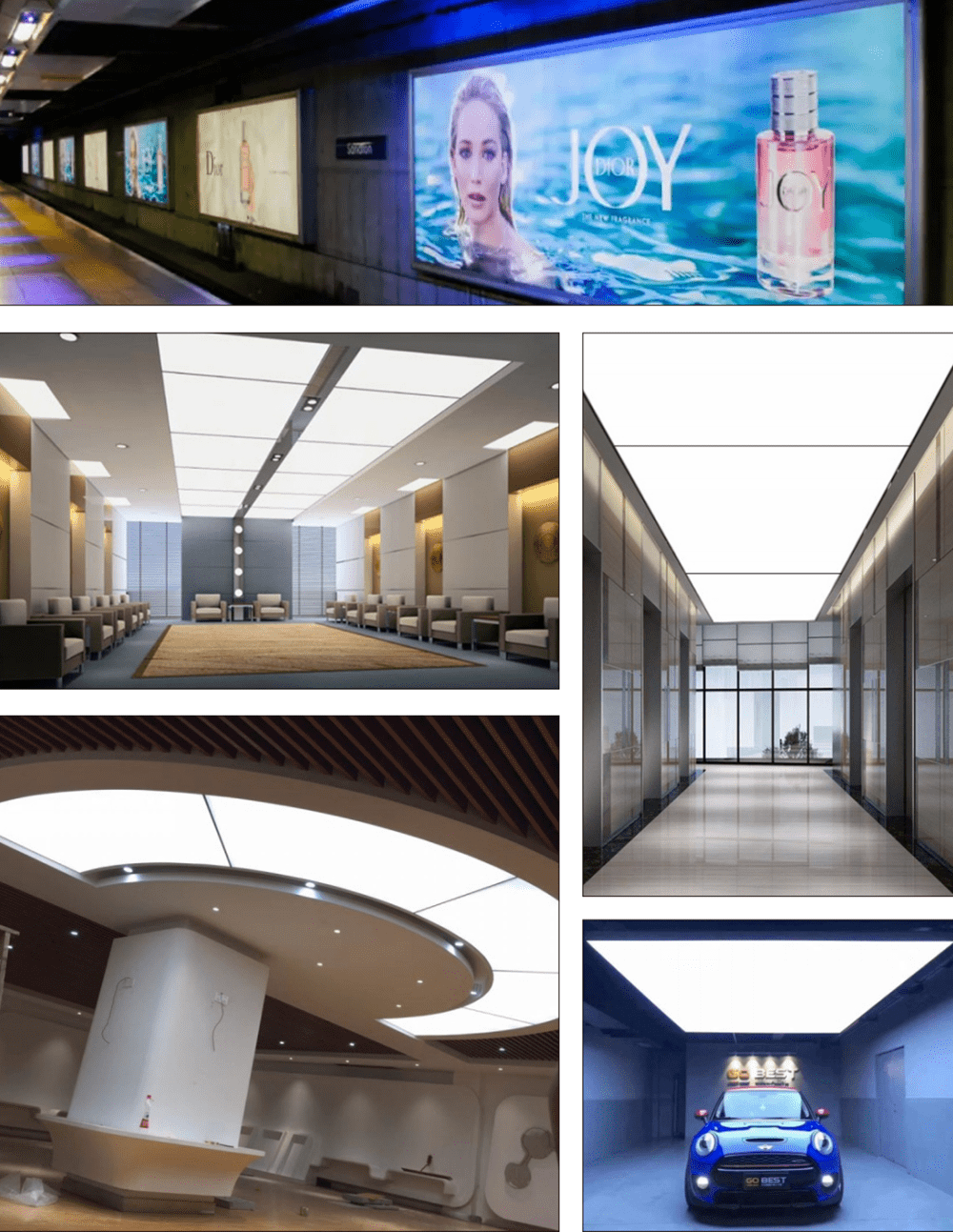

Definitely, LED sheet light can be customized for different designs and shapes and this flexibility is one of the main reasons they are widely used in commercial and architectural backlite lighting projects.

In modern projects, lighting is rarely standard or rectangular. Architects design curved ceilings, illuminated walls, floating shelves, backlit stone panels, and branded feature elements that require precise light distribution. Standard fixtures often limit design freedom. In contrast, custom led sheet lighting allows lighting layouts to adapt to the design rather than forcing the design to adapt to the fixture.

LED sheet lighting systems are built around modular grids of LEDs distributed across a thin flexible panel. Many designs allow cutting along predefined lines, electrical segmentation, and layout expansion. This makes it possible to create uniform illumination across irregular shapes, control brightness levels, and integrate lighting into custom-built elements.

This article explains how customization works in practical B2B terms. It covers physical, optical, and electrical customization, real-world applications, manufacturer-level adaptation, limitations, and a structured decision checklist to support architects, engineers, and procurement teams evaluating a sheet of led lights for commercial use.