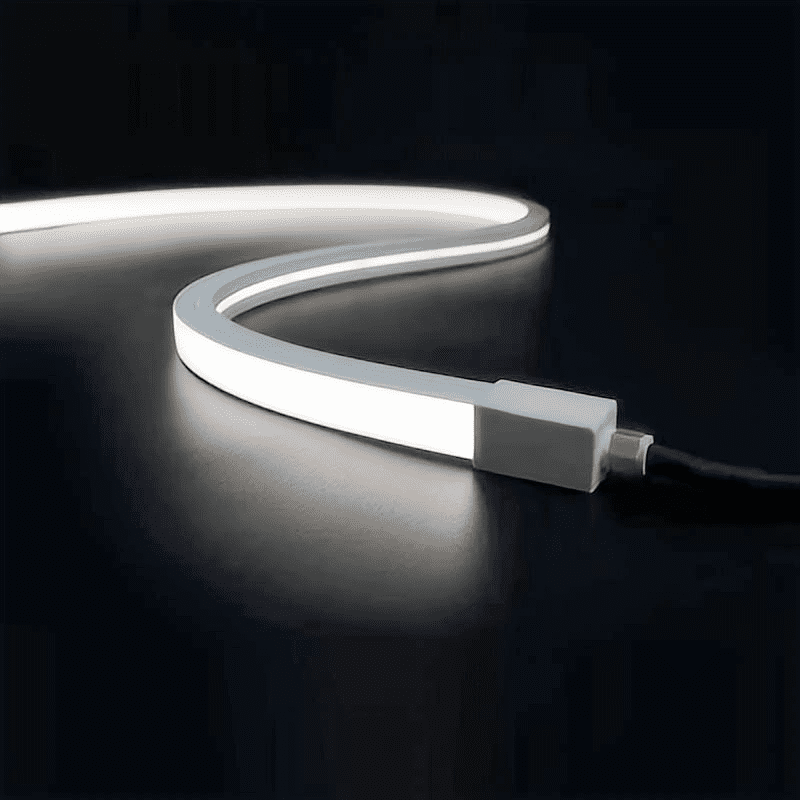

Neon Flex Strip

-Support customization, cutting, sample free.

Unique structure design, uniform lighting surface.

-Environmental protection grade silicone material.

-IP67 protection level, acids & alkalis and UV resistance.

-Excellent toughness, simple and stylish appearance.

-Integrated extrusion molding process with 3-5 years warranty

LED Neon Flex Supplier & Manufacturer

LUMIWISE Lighting is one of top custom LED Neon Flex Strip Light manufactures in China. We offer customized solutions, OEM, ODM service. Wholesalers, distributors, dealers, traders, agents are welcome to purchase in bulk with us.

All our LED Neon Rope Lights are more than IP65 waterproof tested and certificated, ensuring high performance and long lifetime.

If you have customized need for bulk RGB LED Neon, Lumiwise can offer custom LED Neon Flex Strip Light with custom color, size, long, CRI, and various accessories.We can also provide a PCB level customized LED Neon Light solution. With our LED Neon light bulk order serivce, you can get as many projects as possible. Contact us now for more information!

What is LED Neon Flex?

Neon flex strip contains silicone neon and PU neon. Silicone neon is IP67, used indoor or outdoor. PU neon is IP68, used underwater.

Silicone Neon is made by adopting three-color silicone integrated extrusion shaping process, and its protection grade reaches up to IP67, featuring resistances to saline solutions, acid & alkali, corrosive gases, fire, and UV, applying to indoor and outdoor molding decoration, building outlines, city night scenes illuminating, and so forth for the sake of the effect of decorative lighting.

PU Neon is made by TPU U shape milky tube and filling with opal PU glue. Its protection grade reaches up to IP68, UV resistant, and saltwater resistant, used for underwater decorative lighting.

What key features of LED Neon Flex Lighting?

Unlike traditional glass neon lights, which require a high voltage of up to 15,000V for regular operation, the LED neon flex light operates at 12V or 24V and is safe to use as it will not break and has low heat dissipatio

The light source is made of LEDs, which can last up to 50,000 hours. The flexible silicone/PVC/PU gel is also used, so there is no problem breaking like traditional gl

Neon flex strips have low maintenance costs, you don’t have to spend a lot of energy and money on maintenance. Unlike traditional neon signs, it requires no inflation or special handling.

Neon flex strips are a more environmentally friendly lighting solution than traditional neon signs because they contain no toxic gases or heavy metals.

The neon flex strips are easy to install and can be installed with clips, brackets or adhesives. You can install it yourself.

The neon flex strips are available in a variety of colors. At the same time, we also support color temperature customization to match any design aesthetic or brand. This makes it a popular choice for businesses and designers looking to create unique lighting solutions.

LED Neon Flex Lights Application

LED Neon Flex are suitable for indoor and outdoor lighting. Various scenes: bars, cafes, shopping malls, speciality stores, welcome signs, corporate LOGO, decorative pendants, window display festivals, art decorations, corporate publicity, interior decoration, bedrooms, openings, restaurants, wedding hotels, shopping malls and catering, company background wall, etc.

LED Neon Flex Strip Manufacturing Process

Now LED Neon flex is durable and made extra long because our LED neon flex are all a one-piece extrusion process. This process can be defined in a few simple steps:

- First, start by mounting the rolled LED strip lights on a pay-off frame. These LED strips are then adjusted and ordered via the adjustment table.

- Then thread the LED strip lights through the pre-moulded silicon header. Wrap the silicon material on the light bar to activate the operation button of the electric control box. It starts the machine to wrap the material.

- The extrusion machine extrudes the LED strip light, and the product is gradually vulcanized through the vulcanization furnace. Keep the temperature in the oven moderate so as not to burn out the LED lamp beads. After vulcanization, the product is drawn out by a tractor.

Features of One-piece Extrusion LED Neon Flex

- The LED Neon Flex silicone is co-extruded with the LED strip lights. Through mold molding, it can extrude more than one thousand meters at a time. The extrusion size is more standard and the efficiency is high.

- The LED Neon Flex has a hollow outer ring and an arc-shaped inner ring. The glue and lamp beads are peeled off, effectively solving the color difference, and the light output angle is better.

- The LED Neon Flex is extruded by a one-time machine, and the plug and the extruded light strip are integrally formed. It has excellent waterproof performance and will not be corroded by water. The light will not fall off after being soaked in water for a long time.

- LED Neon Flex have excellent light transmittance and refractive index, which can minimize the light attenuation of the light source.

- The color tolerance of LED Neon Flex is smaller, ensuring that the color temperature after sealing is not much different from the actual color temperature, and the color temperature is consistent.

- LED Neon Flex have good acid, alkali and salt resistance. In the environment of a weak acid, weak alkali and weak salt, the appearance of the light strip remains unchanged and can be used normally.

What typical types of neon flex strips ?

Our Hot-selling Silicone neon strip is divided into four series: “Top Bend “, “Side Bend”, “3D series’ and “360° round series”. Customers can choose the most suitable product according to the lighting project, application site, functional requirements, project nature, cost budget and other factors.

Top Bend Series

Top bend series silicone neon flex is made of environmentally friendly silicone material, which is extruded in one piece.

The protection level reaches IP67, which is very suitable for long-term outdoor use, and the surface is not easy to turn yellow.

The light transmittance is extremely high, and it can be used for signboard lighting, indoor and outdoor decorative lighting and architectural contour lighting.

After “9 major tests”, it is resistant to hydrochloric acid, acid and alkali corrosion, flame retardant, and UV resistant, and its quality is reliable and guaranteed.